Oil Fuel Tanker Trailer Materials

Welcome to

DTG Group Oil Tanker Trailer

In this article, we will discuss different materials, they are used to make fuel oil tank semi trailers. Trailer manufacturers use carbon steel, stainless steel & aluminum allow to make fuel tank trailers.

You should know, each of these materials has its advantages & disadvantages. Let us now look at the pros & cons of each material.

Aluminium alloy oil tanker Trailer

The advantages of using aluminum alloy on tank trailers include:

# The trailers are safer & more secure.

# It is lighter in weight than steel.

# Aluminum tank trailer can carry more liquid load.

# The material is resistant to rust & hence it does not pollute the liquid during transportation.

Some of the disadvantages of aluminum allow include:

#1, It is highly prone to stress cracking.

#2, The strength of aluminum is almost half the strength of steel.

#3, Welding aluminum plates is cumbersome.

#4, It is more expensive than carbon steel tanker.

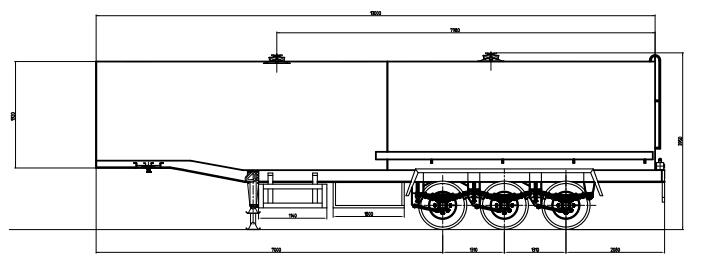

Oil transport tanker semi trailer is mainly used for large oil material, liquid asphalt transportation, tonnage generally at about 30,000 litres to 60,000 litres. Oil transport tanker semi trailer usually are: 2 bridge semi trailer &3 three bridge semi trailer.

Carbon steel and stainless steel tanker trailer.

The main advantages of using carbon and stainless on trailers include:

#1, The price of steel is competitive & hence steel is popular in developing countries.

#2, Steel has high strength and is not damaged easily.

#3, Carbon steel is easy to weld than aluminum.

#4, Steel is less prone to stress crack, which is common with aluminum.

#5, The stainless steel is resistant to rust, it can used to transport edibles.

The main disadvantages of using carbon steel are as below:

#1, Carbon steel tanker requires galvanizing / painting on the surface to prevent rusting.

#2, It has a higher density than aluminum alloy tanker trailer.

#3, It cheaper price than aluminum alloy tanker trailer.