Oil Fuel Tanker Trailers for sale

Fuel tanker trailer for sale information knowledge

Welcome to

DTG Group Oil Fuel Tanker Trailer

1, What is Fuel Tank Trailer?

Petroleum tankers are always comprised of aluminum (but also Carbon steel & stainless steel) materials, and range from 20,000 to 60,000 Litres in size.

Built to safely & efficiently transport liquid fuel, ethanol, diesel, and other petroleum products in bulk, these aluminum Tanker compliant fuel tank trailers are the best solution for businesses in the long run. The multi-compartment design of these trailers enables secure distribution of the product’s weight to limit the effect of the liquid surge while efficiently transporting different types, and grades of different products within a single trip. These fuel semi trailers come equipped with features such as an overfill system, emergency valve, vapor recovery system, and more to ensure the hauling, safe loading, & unloading of hazardous liquid products.

Though some fuel tanks trailers have only 1 compartment in which to store fuel, most modern tanks are comprised of 5 or 6 to allow different freight, or different grades of the same type of product, to be loaded at the same time. By the way, the more Compartments you request, the more price you need to pay.

Using a multi-compartments model, it can reduces the changes of the axle load & hence keeps the trailer stable.

For over 23 years, Trailers of DTG Group China has been offering the highest standard of customer service & expert advice to businesses & individuals in the market for tank semi trailers. With our extensive industry experience & network, we manufacture lots of tank trailers each year, and export at the most competitive prices.

2, Tanker Truck Safety Features.

Liner – Liner is designed to increase the operational time of a tank. Tank liners protect aluminum, steel, stainless steel tanker trailers from the effects of corrosive materials. Many tankers haul solvents & hydrochloric acids with concentrations greater than 21% making a liner is an absolute requirement.

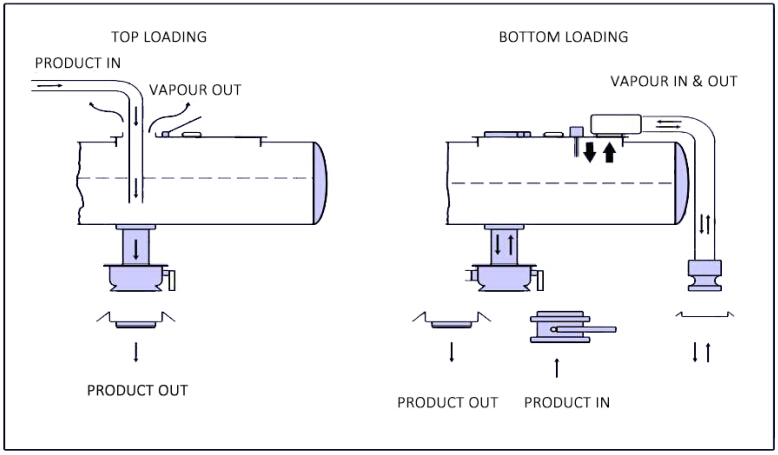

Vapor Recovery Systems – Vapor recovery systems are installed on tankers & at loading platforms that handle cargos that should not be dispersed into the atmosphere. Vapor recovery systems capture errant vapors that happen during the loading / unloading of a product however they return them to the cargo hold. Good vapor recovery systems save money by reducing lost product.

Top or bottom loading – Bottom loading has no explosion risk and hence it is considered safe for the workers.

Bottom loading: The method is recommended for all types of fuel & liquid cargo. It is efficient & safe, because the loading speed is fast. Gasoline gas remains within the internal circulation.

Top loading: Loading liquid /fuels is unsafe & risky. Gasoline evaporates into the atmosphere when loaded from the top. The vapor or fumes increase the risk of an explosion at the filling station.

In addition, the evaporated gas is a loss of the total volume of the cargo. Top loading is also harmful to the workers & hence it should be avoided at all costs. By the way, top loading is more time consuming.

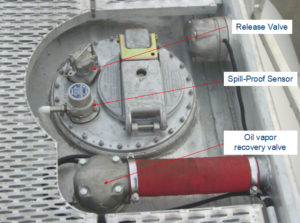

The manhole cover – it is simply the cover on the trailer’s manhole as illustrated in the picture below. The cover has important components, which you should know about it, which keep the tank safe for the trailer.

Pump – Pumps are the mechanisms needed to mix, dispense & blend, heavy, viscous liquids carried in tankers. Pumps are manufactured of different materials & are installed in the tankers to accommodate the type of load. E.g, Stainless steel pumps are necessary when working with corrosive unstable chemicals. This is another element of fuel transport safety which cannot be overlooked.

Fuel outlet valve – This valve is used for quick unloading of the liquid in the tank trailer. Its internal structure complies with fluid mechanics & can minimize internal pressure during a large flow.

The special structure used in the fuel outlet valve help in ensuring that there is no oil leakage when the joint is removed by you.

Skully – A skully system provides grounding verification and overfill protection for tanker trucks. Tankers that haul petroleum & liquid chemicals need automatic and continuous self-checks. Sensors in a skully system provide automatic & continuous self-checking circuitry. This too is a key component in Fuel Transport Safety.

Quality is always the most important thing you should consider when you buy fuel tanker trailer (other types trailer too). All the money you saving before you buy the tanker trailer, it will became a big lost in your future using.

Check our great quality according to below 1 picture:

Happy Oil Fuel Tanker Trailer purchase!